What Are the Benefits of Using Strong Springs in Your Projects?

Strong springs are a crucial component in various mechanical and industrial applications, offering superior durability, flexibility.

Strong springs are a crucial component in various mechanical and industrial applications, offering superior durability, flexibility, and load-bearing capacity. Whether you are working on an automotive project, heavy machinery, or precision engineering, high-quality strong springs ensure the efficiency and longevity of your designs. In Southern California, springs manufacturers provide a wide range of solutions tailored to different project requirements.

How Do Strong Springs Enhance Performance and Longevity?

One of the primary benefits of strong springs is their ability to withstand high-stress conditions without compromising performance. These springs are made from high-tensile materials like stainless steel, carbon steel, and alloy steel, which provide exceptional resilience and durability. When used in applications such as automotive suspensions, industrial equipment, and aerospace mechanisms, strong springs help maintain consistent force distribution and shock absorption, reducing wear and tear over time.

What Are the Key Applications of Strong Springs in Various Industries?

Automotive Industry

Strong springs are widely used in vehicle suspensions, braking systems, and engine components. Their ability to absorb shocks and maintain structural integrity under heavy loads makes them indispensable for ensuring a smooth and safe ride. High-performance vehicles especially rely on strong springs for stability and precision handling.

Manufacturing and Industrial Equipment

Factories and industrial plants use strong springs in machinery that requires precision movement, tension control, and load management. These springs enhance the functionality of presses, conveyor systems, and automated assembly lines, ensuring efficiency and safety in production processes.

Aerospace and Defense

In the aerospace sector, strong springs play a critical role in landing gear mechanisms, aircraft controls, and missile systems. Their ability to endure extreme temperatures and pressures makes them essential for high-risk applications that demand reliability and precision.

Medical Devices

Medical equipment such as surgical instruments, diagnostic machines, and patient care devices often incorporate strong springs to provide controlled motion and force. Their application ensures the reliability of delicate yet crucial mechanisms in healthcare settings.

Construction and Heavy Machinery

Cranes, bulldozers, and other heavy construction equipment rely on strong springs for load balancing, shock absorption, and component stability. Their durability allows these machines to function optimally in rugged environments.

How Do Strong Springs Improve Safety and Reliability?

The strength and resilience of springs directly impact the safety of mechanical and industrial applications. Weak or low-quality springs can lead to failures, accidents, and costly damages. Strong springs prevent sudden breakdowns by absorbing and distributing forces efficiently, thereby ensuring reliable performance. Additionally, they help in vibration reduction, which minimizes wear and tear on surrounding components, extending the life of the entire system.

Why Choose Southern California Springs for Your Project?

When sourcing high-quality strong springs, choosing Southern California springs manufacturers can provide numerous advantages. Many manufacturers in the region specialize in producing custom and precision-engineered springs tailored to specific project needs. These companies use state-of-the-art technology and premium materials to ensure that their products meet industry standards. Whether you need compression springs, torsion springs, or extension springs, The Spring Store offers a comprehensive range of options to meet your requirements.

What Factors Should You Consider When Selecting Strong Springs?

When choosing strong springs for your project, consider the following key factors:

Material Selection

The type of material used significantly impacts the spring’s strength, longevity, and resistance to environmental conditions. Common materials include:

- Stainless Steel – Ideal for corrosion resistance and durability.

- Carbon Steel – Offers high strength and cost efficiency.

- Alloy Steel – Provides excellent toughness and fatigue resistance.

Load Capacity and Stress Resistance

Understanding the load and stress conditions in your application is crucial for selecting the right spring. High-stress environments require springs with enhanced tensile strength and fatigue resistance to ensure longevity and reliability.

Spring Type and Design

Different types of strong springs serve different functions:

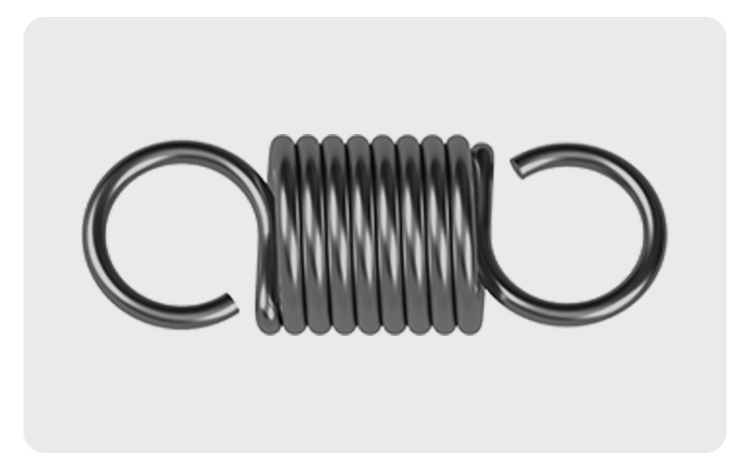

- Compression Springs – Absorb and store energy when compressed.

- Extension Springs – Provide resistance when pulled apart.

- Torsion Springs – Deliver rotational force for various mechanical applications. Choosing the right spring type based on your application needs ensures optimal performance and efficiency.

Environmental Considerations

If your springs will be exposed to harsh environments, consider corrosion-resistant coatings or stainless steel options to prevent deterioration over time. Factors such as temperature fluctuations, humidity, and chemical exposure can impact the longevity of your springs.

How Can You Maximize the Lifespan of Strong Springs?

Proper maintenance and handling can significantly extend the lifespan of strong springs. Here are a few tips to ensure longevity:

Regular Inspection

Check for signs of wear, deformation, or corrosion regularly. Replacing worn-out springs before they fail prevents costly damage and downtime.

Correct Installation

Ensure that springs are installed correctly to prevent excessive stress or misalignment, which can lead to premature failure.

Use of Protective Coatings

Applying protective coatings such as zinc plating, powder coating, or anodizing can help enhance corrosion resistance and extend the service life of your springs.

Proper Storage

Store unused springs in a dry, controlled environment to prevent rust and degradation over time.

Where Can You Find High-Quality Strong Springs?

If you’re looking for reliable, durable, and high-performance strong springs, The Spring Store offers a wide selection to suit various industrial and engineering applications. Their extensive range includes custom and standard springs manufactured with precision and high-quality materials. With a commitment to excellence, The Spring Store ensures that you receive products that meet the highest standards of performance and reliability.

Conclusion: Why Invest in Strong Springs for Your Projects?

Strong springs are essential components in a wide range of industries, providing durability, efficiency, and safety in mechanical applications. Whether you need them for automotive, industrial, aerospace, or medical projects, investing in high-quality springs ensures optimal performance and longevity. By choosing Southern California springs from reputable manufacturers like The Spring Store, you can be confident in the quality and reliability of your components. Prioritizing strong, well-engineered springs in your designs will enhance overall functionality and contribute to the success of your projects.

What's Your Reaction?