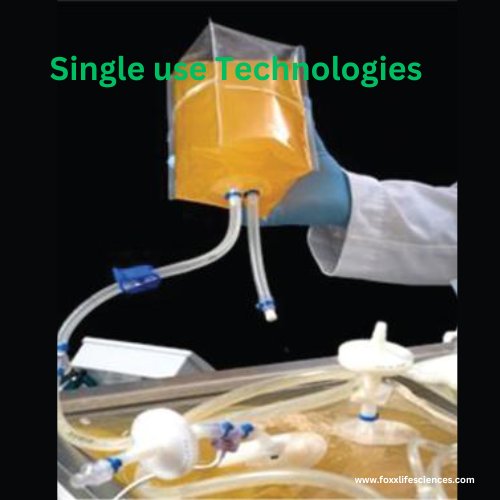

Single use Technologies

In today’s fast-paced world, efficiency and innovation go hand in hand. Single use Technologies have emerged as game-changers, offering scalable, flexible, and cost-effective solutions across industries. From biopharmaceuticals to water treatment, these technologies cater to the growing demand for streamlined processes with minimal environmental impact.

Single-use technologies (SUTs) have revolutionized industries by offering cost-effective, flexible, and contamination-free solutions. These technologies are commonly used in biopharmaceuticals, healthcare, food, and research laboratories to enhance efficiency and reduce operational burdens. With the rising demand for sustainable and efficient manufacturing processes, single-use technologies are becoming an integral part of various industries.

Understanding Single-Use Technologies

What Are Single-Use Technologies?

Single-use technologies refer to disposable components used in manufacturing and research to eliminate cleaning, sterilization, and cross-contamination risks. These include bioreactors, filtration systems, tubing, and disposable sensors.

Key Features of SUTs

-

Pre-sterilized and ready to use: Reduces contamination risks.

-

Flexible and scalable: Easily adaptable for different production scales.

-

Disposable: Eliminates the need for extensive cleaning and validation.

Advantages of Single-Use Technologies

Cost-Effectiveness

Using disposable systems reduces the cost of sterilization, maintenance, and infrastructure setup.

Reduced Risk of Contamination

Pre-sterilized components ensure a contamination-free environment, crucial for biopharmaceutical manufacturing.

Increased Efficiency in Production

SUTs enable rapid changeovers between production batches, minimizing downtime.

Environmental Impact and Sustainability

While single-use systems generate waste, many innovations focus on biodegradable and recyclable materials to mitigate environmental concerns.

Applications of Single-Use Technologies

Biopharmaceutical Industry

SUTs are widely used in vaccine production, monoclonal antibodies, and cell culture processes.

Healthcare and Medical Devices

From IV bags to disposable surgical instruments, SUTs play a vital role in healthcare.

Food and Beverage Industry

Single-use filtration and processing systems ensure hygiene and efficiency in food manufacturing.

Laboratory Research and Diagnostics

SUTs enhance accuracy and reduce contamination in research labs.

Challenges of Single-Use Technologies

-

Waste management: Disposing of plastic-based components responsibly.

-

Scalability: Adapting SUTs for large-scale production.

-

Supply chain dependency: Ensuring a steady supply of raw materials.

Environmental Impact of Single-Use Technologies

Efforts to reduce SUT waste include biodegradable plastics, recycling programs, and sustainable material development.

Single-Use vs. Traditional Stainless-Steel Systems

While traditional stainless-steel systems offer longevity, SUTs provide flexibility, cost savings, and contamination control, making them ideal for modern industries.

Regulations and Compliance in Single-Use Technologies

Regulatory bodies like the FDA and EMA have set strict guidelines for SUT usage to ensure product safety and effectiveness.

Future Trends in Single-Use Technologies

-

Advanced biodegradable materials

-

Automation and smart monitoring

-

Increased adoption in emerging markets

Conclusion

Single-use technologies have transformed multiple industries by offering cost-effective, flexible, and contamination-free solutions. With continuous innovations, these technologies will further improve efficiency, sustainability, and scalability.

What's Your Reaction?