Lead Shot Ballast | High-Density Ballast for Stability and Performance

Nuclead provides high-quality lead shot ballast designed to meet the needs of different industries. Our lead shot is available in various sizes and packaging options, ensuring the perfect solution for any ballast requirement.

Lead shot ballast is a versatile and efficient solution for adding weight to various applications, including marine vessels, industrial equipment, and structural stabilization. Due to its high density and flexibility, lead shot is widely used for ballast systems requiring adjustable and compact weight distribution.

Nuclead provides high-quality lead shot ballast designed to meet the needs of different industries. Our lead shot is available in various sizes and packaging options, ensuring the perfect solution for any ballast requirement. Whether used in sailboats, aircraft, counterweights, or specialized engineering projects, lead shot offers superior stability, durability, and performance.

Why Lead Shot is an Effective Ballast Material

1. High Density for Maximum Weight in a Small Volume

Lead is one of the densest materials available, making it ideal for ballast applications where space is limited. Lead shot allows for significant weight to be added without taking up excessive room, ensuring efficient and compact ballast placement.

2. Adjustable and Easy to Handle

Unlike solid lead ingots or blocks, lead shot can be poured into containers, bags, or cavities, allowing for precise weight adjustments. This flexibility makes it ideal for applications requiring incremental weight modifications.

3. Corrosion Resistance and Long-Term Durability

Lead is naturally resistant to corrosion, making it highly durable in marine and industrial environments. When properly contained, lead shot maintains its integrity for long-term use without significant degradation.

4. Versatile Applications Across Industries

Lead shot ballast is not limited to marine applications. It is used in aerospace, construction, automotive, and sporting industries for counterweights, stabilizers, and impact-resistant solutions.

Applications of Lead Shot Ballast

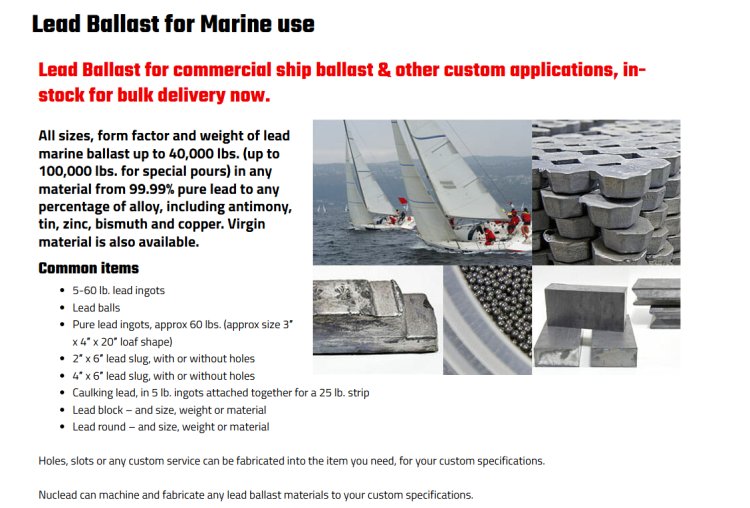

1. Marine and Sailboat Ballast

Sailboats and yachts rely on ballast for stability, preventing excessive tilting and ensuring smooth navigation. Lead shot is commonly used in keels, bilges, and ballast compartments to improve weight distribution and sailing performance.

2. Aerospace and Aviation Weight Distribution

Aircraft and aerospace engineers use lead shot for balancing and counterweight applications. The adjustable nature of lead shot allows precise weight management for optimal flight control and stability.

3. Industrial Machinery and Equipment Stabilization

Heavy machinery and construction equipment use lead shot ballast to counteract vibrations, improve balance, and enhance structural stability. It is often used in cranes, forklifts, and robotic systems.

4. Shooting Ranges and Ammunition Manufacturing

Lead shot is widely used in shooting ranges as a bullet trap material due to its density and ability to absorb impact. It is also a key component in ammunition manufacturing for shotgun shells and specialized ballistic applications.

5. Automotive and Racing Weight Balancing

In auto racing and performance vehicle tuning, lead shot ballast is used to balance weight distribution, improve traction, and optimize handling. This is particularly beneficial for drag racing and off-road vehicles.

6. Counterweights for Industrial and Structural Engineering

Lead shot serves as an effective counterweight in various engineering applications, including elevator systems, stage equipment, and mechanical balancing devices. Its ability to conform to irregular spaces makes it a practical solution for precise weight placement.

Types of Lead Shot Ballast Available

1. Standard Lead Shot

Our standard lead shot is available in various sizes, ensuring a solution for different weight and density requirements. It is commonly used in marine, industrial, and construction applications.

2. Encapsulated Lead Shot

For applications where direct exposure to lead is a concern, encapsulated lead shot is coated with a protective material, such as plastic or polymer, to prevent contact and enhance safety.

3. Custom-Packaged Lead Shot

Nuclead offers custom packaging options, including pre-filled ballast bags, sealed containers, and bulk quantities, allowing for convenient handling and transportation.

Installation and Placement of Lead Shot Ballast

1. Determining the Right Amount of Ballast

Proper weight distribution is crucial for achieving stability and performance. Engineers and designers calculate the required amount of lead shot ballast based on vessel displacement, machinery balance, or counterweight specifications.

2. Strategic Placement for Optimal Weight Distribution

Lead shot ballast should be placed in key areas to maximize its effectiveness. In boats, it is often added to keel compartments, bilge areas, or ballast tanks. In industrial applications, it is used in weighted bases, counterweights, and stability systems.

3. Securing Lead Shot in Place

Depending on the application, lead shot may be contained in bags, sealed compartments, or encased in protective coatings to prevent movement or spillage. Proper securing methods ensure safety and efficiency.

Safety Considerations and Environmental Responsibility

1. Safe Handling of Lead Shot

Although lead is a stable material, it is essential to follow safety guidelines when handling lead shot. Use protective gloves and avoid direct contact with bare skin. Proper ventilation is recommended in enclosed spaces.

2. Environmental Considerations

Lead shot ballast should be sourced from responsible suppliers who follow environmental regulations. Nuclead ensures proper lead recycling and waste management to minimize environmental impact.

3. Proper Storage and Disposal

Lead shot should be stored in dry, secure containers to prevent accidental spillage. If disposal is necessary, it should be done in accordance with local environmental regulations to ensure safe and responsible handling.

Why Choose Nuclead for Lead Shot Ballast?

1. Premium-Quality Lead Shot

Nuclead provides high-density, precision-manufactured lead shot that meets industry standards for ballast applications. Our lead shot is free from impurities and designed for long-lasting performance.

2. Custom Fabrication and Packaging

We offer customized lead shot solutions, including specific size options, encapsulated coatings, and pre-packaged ballast bags tailored to customer requirements.

3. Competitive Pricing and Bulk Availability

Our lead shot is available in various quantities, from small orders to bulk shipments, ensuring cost-effective solutions for individual and commercial needs.

4. Expert Technical Support

Our team of specialists provides guidance on weight calculations, placement strategies, and customization options to help you select the ideal ballast solution.

5. Reliable Supply Chain and Fast Shipping

With an extensive distribution network, we ensure timely delivery of lead shot ballast worldwide. Our efficient logistics system guarantees a steady supply to meet your project deadlines.

Conclusion

Lead shot ballast remains one of the most effective solutions for weight distribution, stability, and performance across various industries. Whether for marine, aviation, industrial, or automotive applications, lead shot provides unmatched density, durability, and flexibility.

Nuclead offers high-quality lead shot ballast tailored to meet diverse customer needs. Our commitment to quality, environmental responsibility, and expert service ensures you receive the best ballast solution for your specific requirements.

If you’re looking for premium lead shot ballast, contact Nuclead today to explore our extensive range of products and solutions.

What's Your Reaction?