Immersion Heater Manufacturers: Pioneering Advanced Heating Solutions for Industrial and Domestic Applications

In today’s rapidly evolving industrial landscape, heating solutions play a crucial role in various applications, ranging from water heating to chemical processing. Immersion heaters have emerged as one of the most efficient and reliable heating solutions, offering precise temperature control and high energy efficiency. Among the leading immersion heater manufacturers, Hindon Heater stands out for its innovative designs, durable products, and cutting-edge heating technologies. This article explores the significance of immersion heaters, their applications, benefits, and how top manufacturers ensure quality and performance in their products.

What are Immersion Heaters?

Immersion heaters are electrical heating devices designed to be submerged in a liquid medium, such as water, oil, or chemicals, to provide direct and efficient heating. These heaters are commonly used in industrial processes, household applications, and commercial settings where controlled heating is essential.

They typically consist of a heating element encased in a protective sheath, ensuring safety and durability. The materials used in manufacturing immersion heaters vary depending on the application, with stainless steel, titanium, and Incoloy being the most common choices.

Types of Immersion Heaters

Leading immersion heater manufacturers produce various types of immersion heaters to cater to different industries and applications. The major types include:

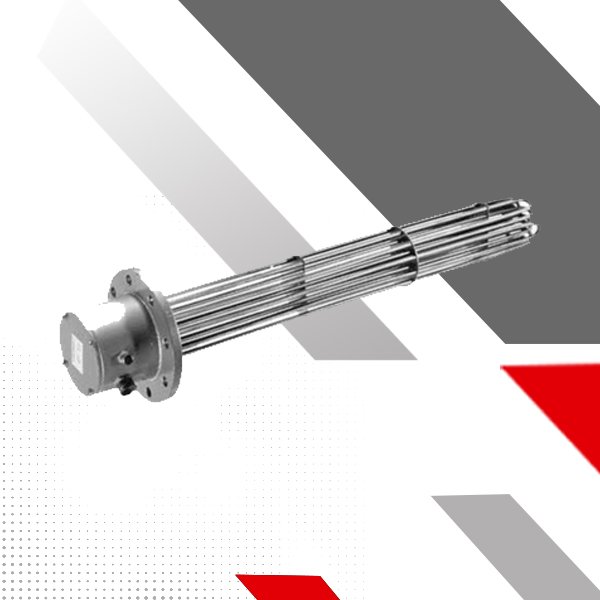

1. Flanged Immersion Heaters

These are commonly used in large-scale industrial applications where high power output and efficient heat transfer are required. Flanged heaters are designed for insertion into tanks and vessels, making them ideal for heating chemicals, oils, and water.

2. Screw Plug Immersion Heaters

These heaters feature a screw-in connection, making them easy to install and replace. They are widely used in water heaters, oil heating systems, and industrial fluid heating applications.

3. Over-the-Side Immersion Heaters

Designed for flexibility, these heaters are positioned over the side of tanks or containers. They are ideal for applications where direct immersion is not possible or where portable heating is needed.

4. Circulation Heaters

These heaters are used in closed-loop systems where a fluid is continuously heated and circulated. They are commonly employed in oil heating, fuel heating, and industrial process heating applications.

5. Steam Table Immersion Heaters

Used primarily in the food industry, these heaters maintain the desired temperature of food and liquids in steam tables and warming stations.

Key Industries That Use Immersion Heaters

Immersion heaters find applications in a wide range of industries. Some of the key sectors that benefit from these heating solutions include:

1. Chemical and Petrochemical Industry

Industries involved in chemical processing and petrochemical refining require precise temperature control for various chemical reactions. Immersion heaters are used to heat aggressive liquids, including acids and solvents, without compromising safety.

2. Oil and Gas Industry

In the oil and gas sector, immersion heaters are used to prevent the solidification of crude oil and other petroleum-based products. They ensure smooth fluid flow by maintaining optimal temperatures.

3. Food and Beverage Industry

From pasteurization to food processing, immersion heaters play a vital role in ensuring food safety and quality. They are commonly used in dairy processing, brewing, and beverage manufacturing.

4. Water Treatment and Filtration

Immersion heaters are crucial for maintaining the temperature of water treatment systems, preventing freezing, and enhancing the effectiveness of filtration processes.

5. Automotive Industry

In automotive manufacturing, immersion heaters are used for preheating engine oil, coolant fluids, and battery heating applications, ensuring optimal vehicle performance in extreme temperatures.

6. Pharmaceutical Industry

Pharmaceutical manufacturers rely on immersion heaters for sterilization processes, temperature-sensitive drug formulations, and laboratory applications requiring controlled heating.

Why Choose Reliable Immersion Heater Manufacturers?

Selecting a reputable immersion heater manufacturer is crucial for ensuring product reliability, energy efficiency, and safety. Here are some key factors to consider when choosing an immersion heater manufacturer:

1. Quality Assurance and Certifications

Top manufacturers adhere to international quality standards such as ISO certification, CE marking, and RoHS compliance to guarantee the safety and performance of their products.

2. Customization and Design Flexibility

Leading immersion heater manufacturers offer customizable solutions to meet specific application needs. Custom-designed heaters ensure better performance and efficiency for specialized industrial processes.

3. Advanced Materials and Technologies

The use of high-quality materials like stainless steel, Incoloy, and titanium enhances the durability and corrosion resistance of immersion heaters. Manufacturers that invest in advanced heating technologies deliver superior products.

4. Energy Efficiency and Cost Savings

Energy-efficient immersion heaters reduce operational costs by minimizing power consumption. Manufacturers that focus on energy-saving designs contribute to sustainable heating solutions.

5. Customer Support and After-Sales Services

Reliable manufacturers provide technical support, installation guidance, and maintenance services to ensure smooth operation and long-term performance of immersion heaters.

Hindon Heater: A Trusted Name in Immersion Heater Manufacturing

Among the top immersion heater manufacturers, Hindon Heater has established itself as a leader in the industry. With a commitment to innovation, quality, and customer satisfaction, Hindon Heater offers a wide range of immersion heating solutions for diverse applications.

Why Choose Hindon Heater?

-

High-Quality Materials: Using premium-grade stainless steel, Incoloy, and titanium for superior durability.

-

Customization Options: Tailor-made heating solutions for specific industrial requirements.

-

Advanced Technology: Incorporating the latest heating elements for enhanced efficiency.

-

Energy-Efficient Designs: Reducing operational costs while maximizing heating performance.

-

Comprehensive Support: Providing expert assistance from selection to installation and maintenance.

Conclusion

Immersion heaters are indispensable in various industries, offering efficient and reliable heating solutions. Choosing the right immersion heater manufacturers ensures durability, energy efficiency, and optimal performance for industrial and domestic applications. Companies like Hindon Heater continue to lead the industry by delivering high-quality, innovative, and customizable heating solutions. Whether you require immersion heaters for chemical processing, oil heating, or water treatment, partnering with a trusted manufacturer guarantees long-term reliability and efficiency.

For more details about high-performance immersion heaters, visit Hindon Heater and explore their wide range of industrial heating solutions.

What's Your Reaction?