The global Chloromethane Market Outlook reveals a steadily growing industry with significant developments on the horizon. As of 2023, the chloromethane market stood at an impressive volume of approximately 4,031.3 kilotons (KT), with projections indicating a compound annual growth rate (CAGR) of 3% between 2025 and 2034. By 2032, the market is expected to reach a volume of 5,188.8 KT. Among the various types of chloromethane, methyl chloride leads the charge, holding around 50% of the market share. This growth trajectory signals an expanding demand for chloromethane, driven by multiple industries, including chemicals, pharmaceuticals, and agriculture.

Understanding the dynamics of the chloromethane market involves analyzing both supply-side and demand-side factors. Supply chains are increasingly shaped by production technologies, regulatory environments, and regional manufacturing hubs. Meanwhile, the demand side is influenced by key industrial sectors, technological advancements, and changing consumer preferences. This article provides an in-depth examination of these factors, offering insights into both current market conditions and future opportunities.

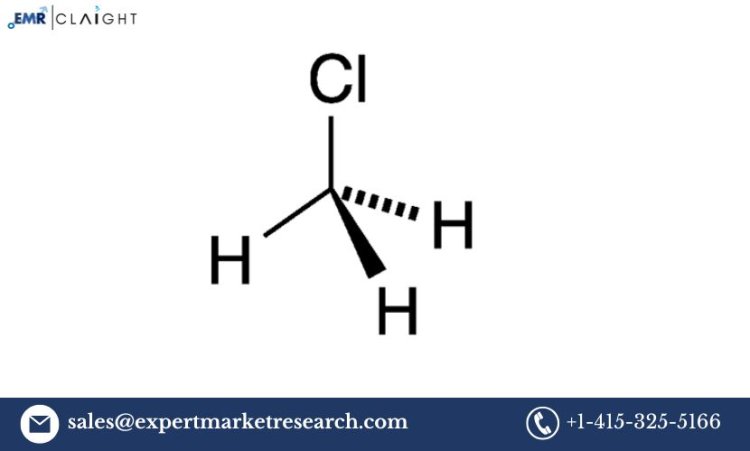

What is Chloromethane?

Chloromethane, also known as methyl chloride, is a versatile chemical compound commonly used as a raw material in the production of silicon polymers, agrochemicals, and pharmaceuticals. The most widely used form of chloromethane, methyl chloride, serves as a precursor to a variety of important chemicals, such as the production of silicones and various refrigerants. Additionally, it is used as a solvent and in the synthesis of several industrial chemicals.

Chloromethane is produced primarily through the reaction of methane with chlorine gas, which results in methyl chloride. Other chloromethane derivatives include dichloromethane (methylene chloride), chloroform, and carbon tetrachloride. These derivatives are vital in diverse industries, which contributes to the global demand for chloromethane compounds.

Get a Free Sample Report with Table of Contents@

https://www.expertmarketresearch.com/industry-statistics/chloromethane-market/requestsample

Key Market Drivers and Trends

The growing demand for chloromethane is primarily driven by the increasing use of methyl chloride in the production of silicones, which are in high demand in industries ranging from construction to electronics and healthcare. Additionally, methyl chloride is used in the manufacture of agricultural chemicals, particularly pesticides, where its role as a solvent and reaction agent is indispensable.

1. Industrial Demand Surge Silicone is one of the fastest-growing applications for chloromethane. In recent years, the global push toward sustainability and energy-efficient materials has significantly boosted the demand for silicon-based products. The electronics, automotive, and construction sectors rely heavily on silicon, particularly for applications such as sealants, coatings, and lubricants. Furthermore, chloromethane’s use in agrochemicals—especially for the synthesis of herbicides and fungicides—has also led to increased demand, particularly in emerging economies where agricultural output is growing.

2. Agricultural Advancements As global populations rise, the agricultural industry faces mounting pressure to improve crop yields. Chloromethane derivatives are essential in the development of agrochemicals like herbicides and pesticides, which play an integral role in enhancing agricultural productivity. The continued shift toward more efficient, precision-based farming technologies is also expected to spur demand for specialized agrochemical formulations, many of which rely on chloromethane compounds.

3. Increasing Focus on Pharmaceuticals The pharmaceutical industry is another key driver in the chloromethane market. Methyl chloride is used in the synthesis of several pharmaceutical intermediates, which are essential in the production of key medications. For instance, methanol, a derivative of chloromethane, is used in the manufacturing of several important drugs, including certain cancer treatments.

Regional Supply and Demand Dynamics

North America and Europe have long been dominant players in the chloromethane market. These regions benefit from strong chemical production infrastructure, robust demand from the automotive and construction sectors, and well-established regulations that ensure safe and efficient chemical production processes. For example, in the United States, major chemical producers like Dow and Eastman Chemical Company have advanced technologies for producing chloromethane derivatives. These companies are increasingly leveraging renewable feedstocks and improving production efficiencies to remain competitive.

On the other hand, Asia-Pacific is emerging as the fastest-growing market, driven by rapid industrialization, urbanization, and agricultural advancements. China, in particular, has become a global manufacturing hub for chemical production, including chloromethane. The expansion of China’s agricultural and chemical industries is expected to further boost the demand for chloromethane in the region. Additionally, the rise of other developing markets like India and Southeast Asia presents significant growth opportunities.

Latin America and the Middle East & Africa are relatively smaller markets but are poised for steady growth. These regions are increasing their chemical manufacturing capacities, particularly in petrochemical complexes, and are seeing growing demand for chloromethane in agricultural and industrial applications.

Supply Chain Considerations

The supply of chloromethane is largely concentrated in a few key regions. The primary raw materials for chloromethane production are methane and chlorine, both of which are abundant but must be sourced and transported efficiently. Changes in global energy prices, logistical disruptions, or regulatory changes related to chlorine production could affect the availability and cost of chloromethane.

In terms of production, the chlor-alkali process (which produces chlorine and sodium hydroxide as by-products) is the most common method for producing chloromethane. This process is energy-intensive, meaning fluctuations in energy prices, particularly natural gas, can impact production costs. Additionally, technological advancements, such as the development of more energy-efficient production processes, could help stabilize costs and supply.

The chloromethane market is also highly sensitive to regulatory changes. Given the environmental and health concerns associated with chlorinated compounds, manufacturers must adhere to stringent safety and environmental standards. In regions like the European Union and the United States, regulations around the use of chloromethane and its derivatives are well-established and continue to evolve. As such, manufacturers are increasingly adopting green chemistry techniques and developing low-emission production methods to comply with regulations.

Challenges

While the chloromethane market shows promising growth, there are several challenges that stakeholders must navigate:

1. Environmental Concerns :The environmental impact of chloromethane and its by-products remains a significant challenge. Chloromethane, along with its derivatives, can have adverse effects on human health and ecosystems if not managed properly. This has led to increased pressure for manufacturers to adopt more sustainable practices, including recycling and reducing the emissions associated with chloromethane production.

2. Competition from Alternative Chemicals:The rise of bio-based chemicals and alternative solvents is also a challenge to the chloromethane market. As industries increasingly seek to reduce their reliance on petrochemicals, bio-based alternatives could limit the growth potential for chloromethane. However, given the specific applications of chloromethane, its role is likely to remain indispensable in many sectors, even as alternative options are explored.

3. Technological Innovations: On the other hand, there are significant opportunities in the form of technological advancements. The development of more energy-efficient, environmentally friendly production methods for chloromethane presents opportunities to reduce production costs and environmental impacts. Companies investing in research and development to improve the synthesis and end-use applications of chloromethane stand to gain a competitive advantage in the market.

Market Outlook and Future Trends

Looking forward, the chloromethane market is expected to continue its upward trajectory. As industries such as electronics, pharmaceuticals, and agriculture evolve, their reliance on chloromethane derivatives is likely to expand. The growth of emerging markets, particularly in Asia-Pacific, will drive global demand, while technological and regulatory advancements will shape the supply chain.

Manufacturers that can adapt to changing regulations, develop environmentally sustainable production methods, and capitalize on emerging applications will be well-positioned for long-term success. Additionally, as industries increasingly prioritize circular economies, innovations in recycling chloromethane or producing it from renewable resources could play a pivotal role in shaping the future of the market.

Media Contact